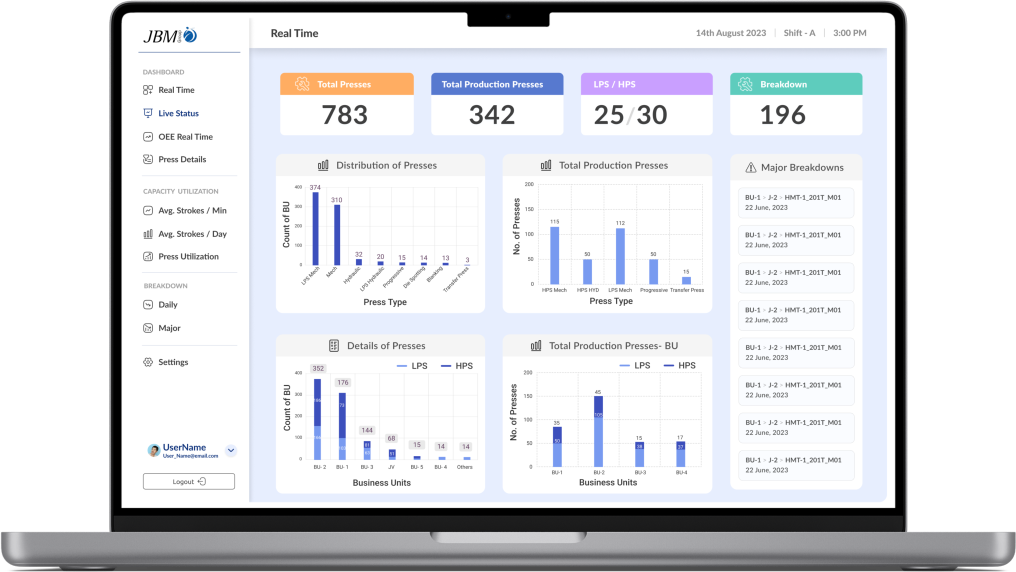

At its core, our Machine Monitoring Solution is a comprehensive and intelligent system designed to provide real-time insights into the performance of your machines and production lines. It empowers you with valuable data, analytics, and visualization tools that enable data-driven decision-making, proactive maintenance, and continuous process improvement.

Real-time monitoring of machine status, cycle times, downtime reasons, and production rates offers unparalleled visibility into the heart of your manufacturing process. This, in turn, helps identify bottlenecks, optimize workflows, and make informed decisions to boost overall efficiency.

Our solution can be used for machine monitoring of different types of machines like stamping, blanking, reeling, peeling, welding, and die casting.

Machine monitoring is a crucial aspect of industrial automation because it provides real-time visibility into the performance, health, and efficiency of machines across the production line. Here's why it matters:

Historical Analysis: Machine data enables long-term performance tracking and helps with strategic decisions like when to upgrade or replace equipment.

Avoid Downtime: Monitoring detects early signs of wear, overheating, vibration, or failure so maintenance can be scheduled before breakdowns happen.

Anywhere Monitoring: With IoT-enabled systems, machines can be monitored remotely, increasing convenience and reducing the need for on-site supervision.

Trusted by leading companies across industries

Velocity Automation's objective is to establish itself as a leader in the global automation market by providing high-quality solutions to industries worldwide.

+91 98182 93887

info@velocityautomation.co.in,

sales@velocityautomation.co.in

Plot No. 2334 HBH Colony, Sector 28,

Mathura Road Faridabad, Sector 28,

Haryana- 121003 ,India

© 2025 Velocity Automation LLP. All rights reserved.